The world of sunglasses is evolving rapidly. With the rise of new technologies and materials, the future of plastic sunglasses manufacturing is bright. In this article, we will explore the key trends and advancements shaping the industry, from innovative sunglasses design to the production process of plastic frames.

The Rise of Plastic Frames

Plastic frames have become a popular choice for sunglasses manufacturers. They are lightweight, durable, and available in a variety of colors and styles. This versatility makes plastic an ideal material for crafting stylish and functional eyewear.

Advantages of Plastic Sunglasses

- Lightweight: Plastic frames are lighter than metal frames, making them more comfortable to wear for long periods. This comfort factor is crucial for consumers who wear sunglasses daily, as it reduces strain on the nose and ears. Additionally, the lightweight nature of plastic makes it easier to incorporate into various designs without compromising on style.

- Durable: Modern plastics are incredibly durable, meaning they can withstand daily wear and tear. This durability is particularly important for active individuals who need eyewear that can handle different environments and activities. The resilience of plastic ensures that sunglasses maintain their shape and appearance over time, providing long-lasting wear.

- Variety: Plastic allows for a wide range of designs and colors, offering consumers more choices. With the ability to mimic other materials and incorporate vibrant colors, plastic frames are highly customizable. This variety caters to a wide demographic, from fashion-forward individuals to those seeking classic styles.

Environmental Impact

While plastic offers numerous benefits, its environmental impact cannot be ignored. Manufacturers are increasingly exploring eco-friendly plastics and recycling programs to address sustainability concerns. By choosing biodegradable materials and implementing recycling initiatives, the industry aims to reduce its carbon footprint and appeal to environmentally conscious consumers.

To understand information related to eco-friendly materials, please refer to How to choose eco-friendly sunglasses

Cost-Effectiveness

Plastic frames are generally more cost-effective to produce than their metal counterparts. This affordability enables manufacturers to offer high-quality products at competitive prices, making stylish eyewear accessible to a broader audience. The lower production costs also allow for frequent style updates, keeping up with ever-changing fashion trends.

Innovations in Sunglasses Design

The design of sunglasses has come a long way from simple, functional frames. Today, designers are pushing boundaries to create eyewear that is both fashionable and practical.

Trendy Designs

- Bold Colors: Bright, bold colors are in vogue, allowing wearers to express their personalities through their sunglasses. These vivid hues can transform a simple accessory into a statement piece, enhancing personal style and confidence. Designers often draw inspiration from current fashion trends, seasonal palettes, and cultural influences to create eye-catching designs.

- Unique Shapes: From oversized frames to geometric shapes, designers are experimenting with new silhouettes. These innovative forms challenge traditional aesthetics, offering consumers a fresh perspective on eyewear fashion. Unique shapes can also enhance facial features, providing a flattering fit for different face shapes and sizes.

- Eco-Friendly Options: Many brands are focusing on sustainability by using recycled plastics and eco-friendly materials. This shift towards green design reflects a growing awareness of environmental issues within the industry. Eco-friendly sunglasses not only reduce waste but also appeal to consumers who prioritize ethical and sustainable products.

Technological Integration

The integration of technology into sunglasses design is an emerging trend. Features such as blue light filters, anti-reflective coatings, and UV protection enhance the functionality of eyewear, addressing modern lifestyle needs. These technological advancements ensure that sunglasses are not just fashion accessories but also essential tools for eye health.

Customization and Personalization

Personalization is becoming increasingly important in the sunglasses industry. Consumers can now customize their eyewear with personalized engravings, interchangeable lenses, and bespoke color combinations. This level of customization allows individuals to create a product that truly reflects their identity and preferences.

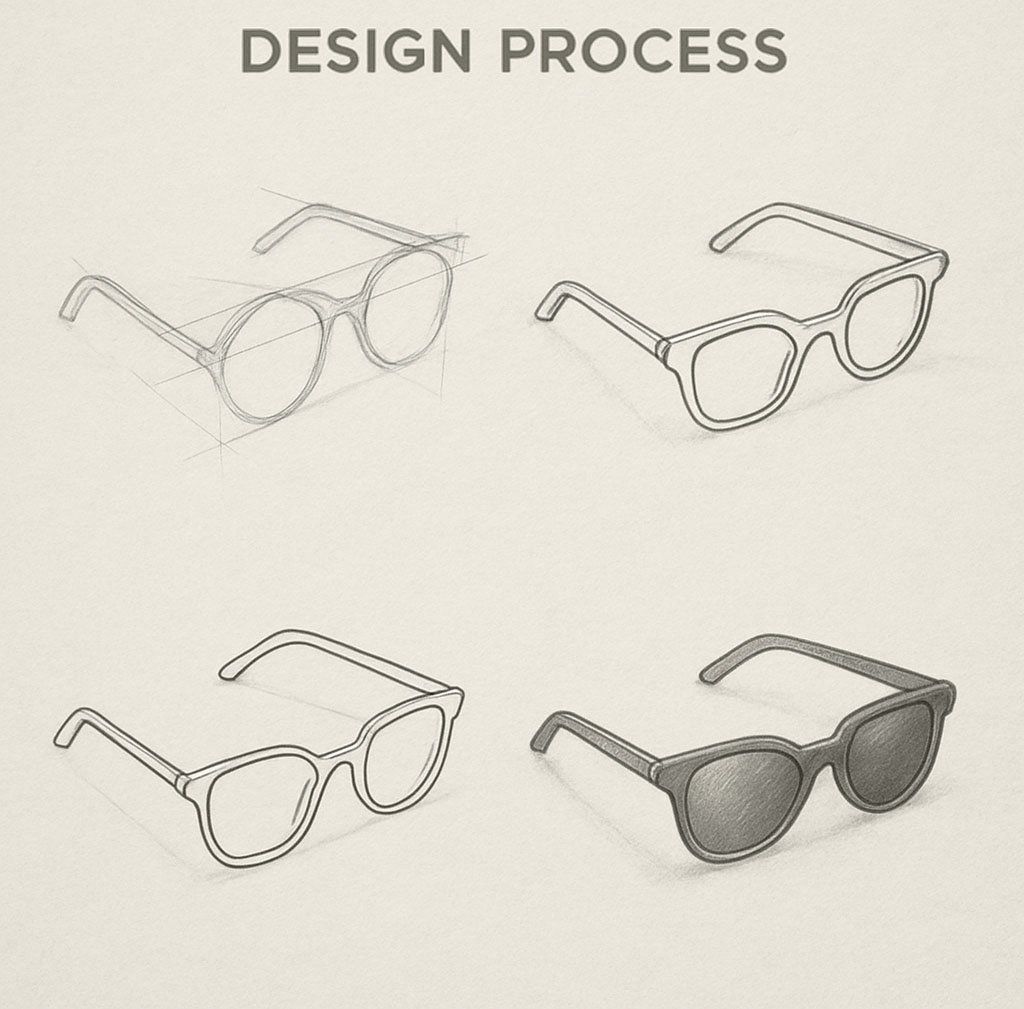

The Production Process of Sunglasses

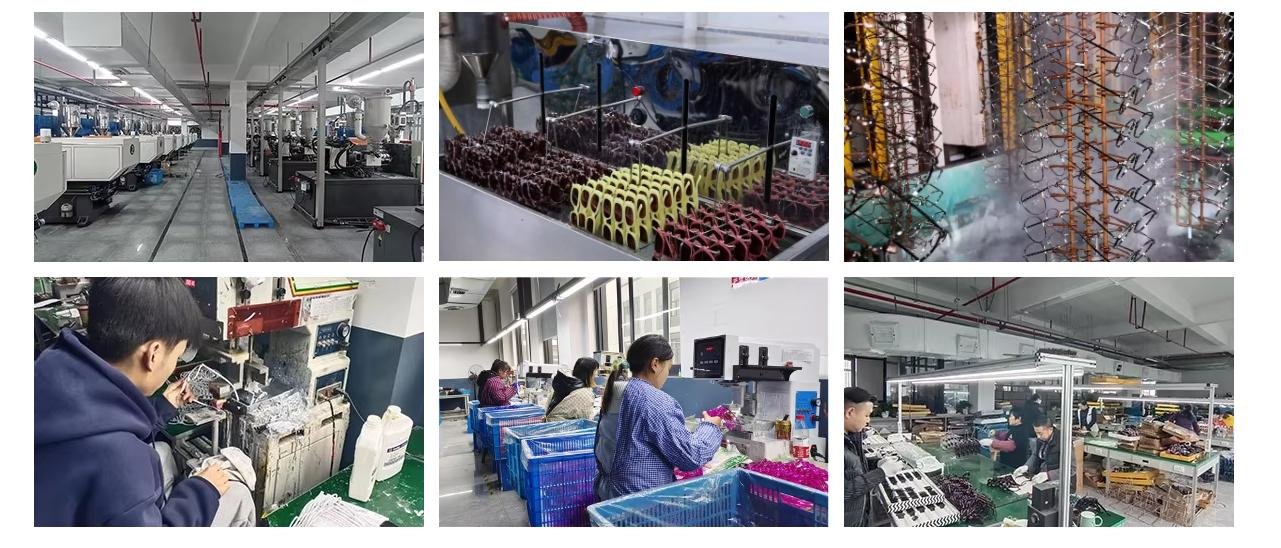

The process of making plastic sunglasses involves several stages, each crucial for ensuring quality and style. Let’s break down the steps involved in the production process.

Designing the Frame

The first step is designing the frame. Designers use CAD software to create detailed sketches and 3D models of the sunglasses. This allows them to visualize the final product and make necessary adjustments before moving to production. The use of digital tools enhances precision and efficiency, ensuring that each design meets both aesthetic and functional criteria.

Selecting Materials

Once the design is finalized, we choose the materials. For plastic sunglasses, this typically involves selecting high-quality polymers that offer durability and flexibility. The choice of material can also influence the weight, texture, and finish of the final product. We often collaborate with material scientists to develop innovative plastics that meet specific performance standards.

Molding

The chosen plastic is then molded into shape. This involves heating the plastic and using molds to form the frames. Precision cutting tools are used to ensure each frame is perfectly shaped. Advanced molding techniques allow for intricate designs and consistent quality while minimizing material wastage during production.

Fixed hinge

Hinges, nose pads, and other metal parts are welded using ultrasonic welding or fixed with screws to ensure an opening and closing lifespan of over 10,000 times.

spray painting

The spray painting process for glasses is a crucial step in the surface treatment of the frames, directly affecting the product’s appearance, durability, and texture.The sprayed framework is now ready for the next drying step. In the drying room, natural air drying typically takes 8-24 hours, depending on the outdoor temperature. If needed, the room can be heated to accelerate the drying process.

Lens cutting

The CNC cutting machine shall be debugged several times before cutting the original lens into a shape that matches the frame. After cutting, the pieces will be manually inserted into the frame.Cutting demo lenses and sun lenses is a vital step in the manufacturing and assembly process for both eyeglasses and sunglasses

Priting logo

Printing a brand logo or pattern on the temples of sunglasses is a common branding technique. The appropriate method should be chosen based on the material, design effect, and cost.

Assembly

After molding, the frames are assembled with lenses. This is a meticulous process that requires attention to detail to ensure that the lenses fit securely. Skilled technicians handle the assembly to maintain high standards of craftsmanship and functionality. The fitting of lenses involves precise measurements and adjustments to achieve optimal clarity and comfort.

Cleaning and Drying

After inspection, all the fingerprints and dirt on the frame and lenses will be cleaned in an ultrasonic cleaning machine. This will be done before putting glasses into the dryer.

Quality Control

Quality control is a critical step. Each pair of sunglasses undergoes rigorous testing to ensure they meet safety standards and are free from defects. This includes checking for lens alignment, frame symmetry, and durability under various conditions. Quality assurance protocols are continually updated to incorporate the latest safety regulations and industry best practices.

Packaging

Once the sunglasses pass quality control, they are carefully packaged for distribution. Packaging is designed to protect the product during transit and enhance the unboxing experience for consumers. Manufacturers often include care instructions and protective cases to prolong the lifespan of the sunglasses. Distribution channels are optimized to ensure timely delivery to retail partners and direct customers.

Future Technologies in Sunglasses Manufacturing

3D Printing

3D printing is revolutionizing the production process. It allows for rapid prototyping, reduced waste, and more complex designs. This technology is set to become a staple in manufacturing, offering endless possibilities for customization. With 3D printing, manufacturers can quickly iterate on designs, respond to market trends, and produce limited edition pieces with minimal overhead.

Smart Sunglasses

The integration of technology into eyewear is another exciting development. Smart sunglasses can include features like Bluetooth connectivity, audio capabilities, and augmented reality. These innovations open new doors for functionality and user experience. As wearable technology evolves, sunglasses are poised to become multifunctional devices that enhance everyday life.

Sustainable Manufacturing

As environmental concerns grow, the industry is moving towards sustainable practices. This includes using biodegradable materials and implementing eco-friendly production processes to reduce the environmental impact. Innovations in recycling technologies and renewable energy sources are also being explored to create a more sustainable supply chain. Brands that prioritize sustainability are likely to attract environmentally conscious consumers and set new industry standards.

Advanced Lens Technology

Advancements in lens technology are enhancing the performance of sunglasses. Innovations such as photochromic lenses, polarized filters, and anti-scratch coatings improve visual clarity and protection. These technologies cater to diverse consumer needs, from outdoor enthusiasts to urban commuters. As research progresses, we can expect even more sophisticated lens options that adapt to various lighting conditions and activities.